Ozonation of lignocellulosic waste for ethanol production

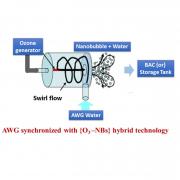

Lignocellulosic waste (in this study municipal trimming) is a promising sustainable feedstock for ethanol production, but require costly and polluting pretreatment, that often result in toxic byproducts. Ozonation is a nonpolluting, effective pretreatment method, but is not used commercially due to the high energy requirements of the assumingly high ozone doses needed. Results demonstrated that both ozonation time and enzyme dose (at optimal pH) impact conversion efficiency to glucose. Ozonation (15 and 90 min, accumulated TOD=318 and 1114 mgO3/L) of water-submerged waste (at pH=5.5) prior to enzyme addition at (×1.5 industrial enzyme dose) enabled high conversion of the cellulose fraction of the waste to glucose (31% and 42% respectively) compared to non-ozonated sample (with enzyme, 12%), suggesting ozonation could offer an effective and feasible pretreatment method. In these ozone doses, only 20% and 40% of the lignin was degraded showing that there is no need for delignification (as opposed to the common hypothesis) to obtain high sugar conversion. In addition, ozone process can be easily monitored by change in absorbance at 230, 280 and 436 nm, making it useful to use spectral scan in the field. Moreover, reduction in net calculated energy balance was obtained at higher ozone dose (90 min compared to 15 or 30 min), demonstrating increased process efficiency at lower ozone doses. Consequently, ozonation can be generated on-site and on demand, enabling decentralized pretreatment operated near the feed source thus overcoming transportation costs.